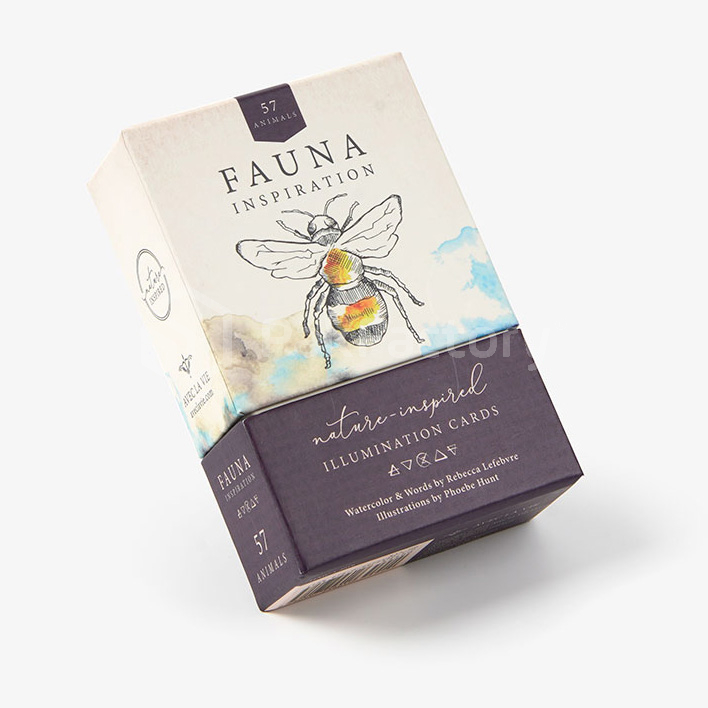

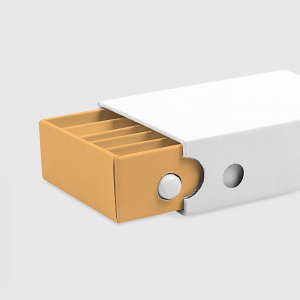

Uncoated Printed Pattern Box with Lid

Key Features

- Detachable and easy-to-remove lid feature.

- Handy and lightweight

- Color, design, size, coating, and paper mounting customization available.

- Premium quality grey board for maximum safety of products.

- Additional options available to enhance your brand

Overview

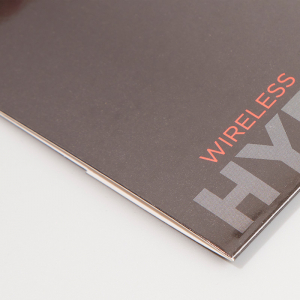

Our boxes with detachable lid have a unique appearance and aesthetic appeal. The detachable lid feature makes these boxes standout from all other products in the surroundings, attracting a larger number of buyers. Furthermore, the detachable lid makes opening and closing of the box extremely easy and hassle-free.

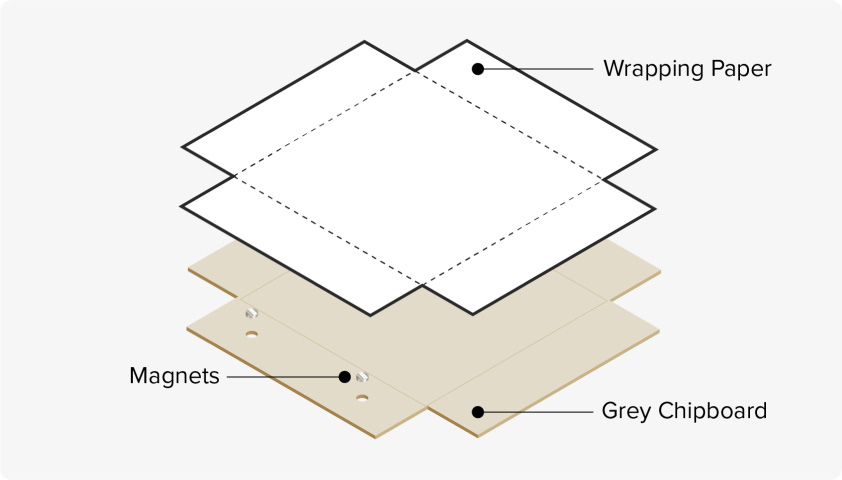

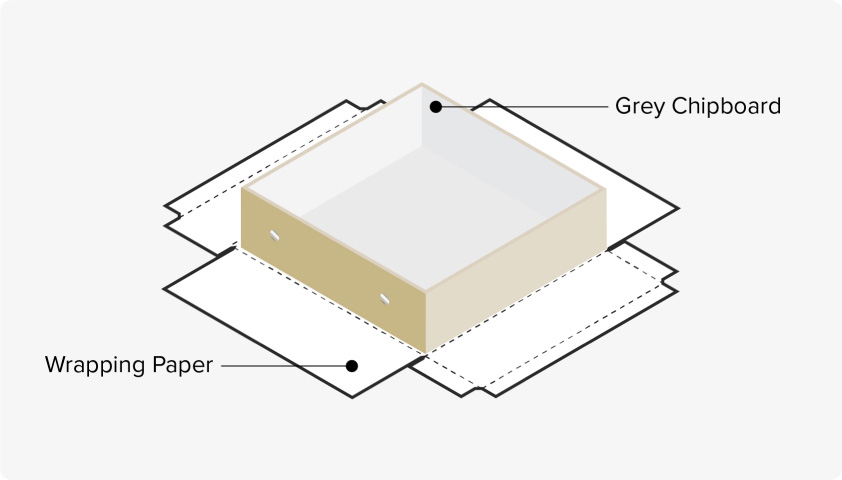

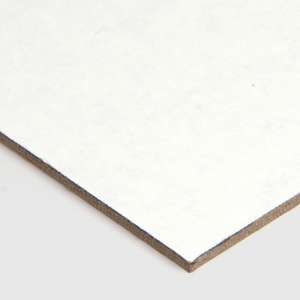

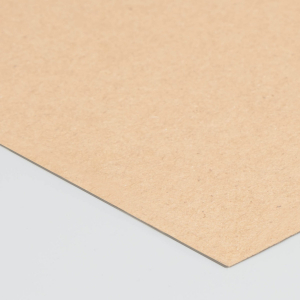

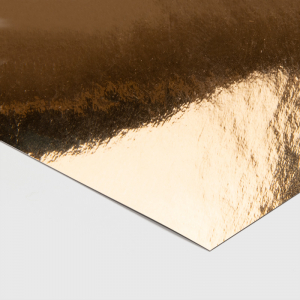

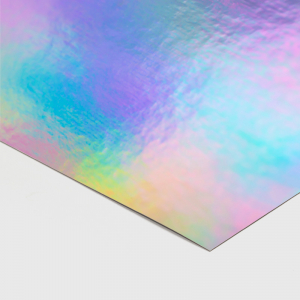

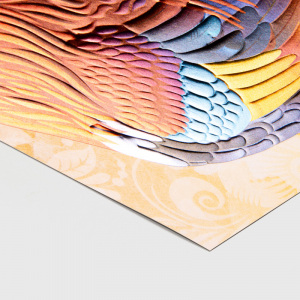

The quality of our uncoated printed pattern box is exceptional. Each of our boxes is made using high quality grey boards that are mounted with paper. You can choose between numerous paper mounting options including metallic, art, uncoated or coated, textured, and many more.

Our uncoated printed pattern box with detachable lid can be customized to reflect your branding strategy. You can add your logo, tagline, images, and product information on 5 sides of the box to make it look much more appealing and valuable. At PakFactory, we let our clients design their own boxes by selecting their desirable size, color, print, coating, and material.

We have a variety of box coating options available including matte or gloss lamination, matte or gloss UV, AQ coating, and many more. The UV coating is ideal for cosmetic products and helps prevent the packaged products from sun damage. If you have a special design request that you don’t find mentioned on this page, then talk to our representative and we will arrange it for you.

Materials

Wrapping Paper Options

Printing Methods

Inks

Finishing

Add-on

Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!